CV

A summary of my CV is on LinkedIn at Martin Cowen on LinkedIn

For a full CV in Word or PDF format, please email me: work at martincowen.me.uk

Career History

Degree

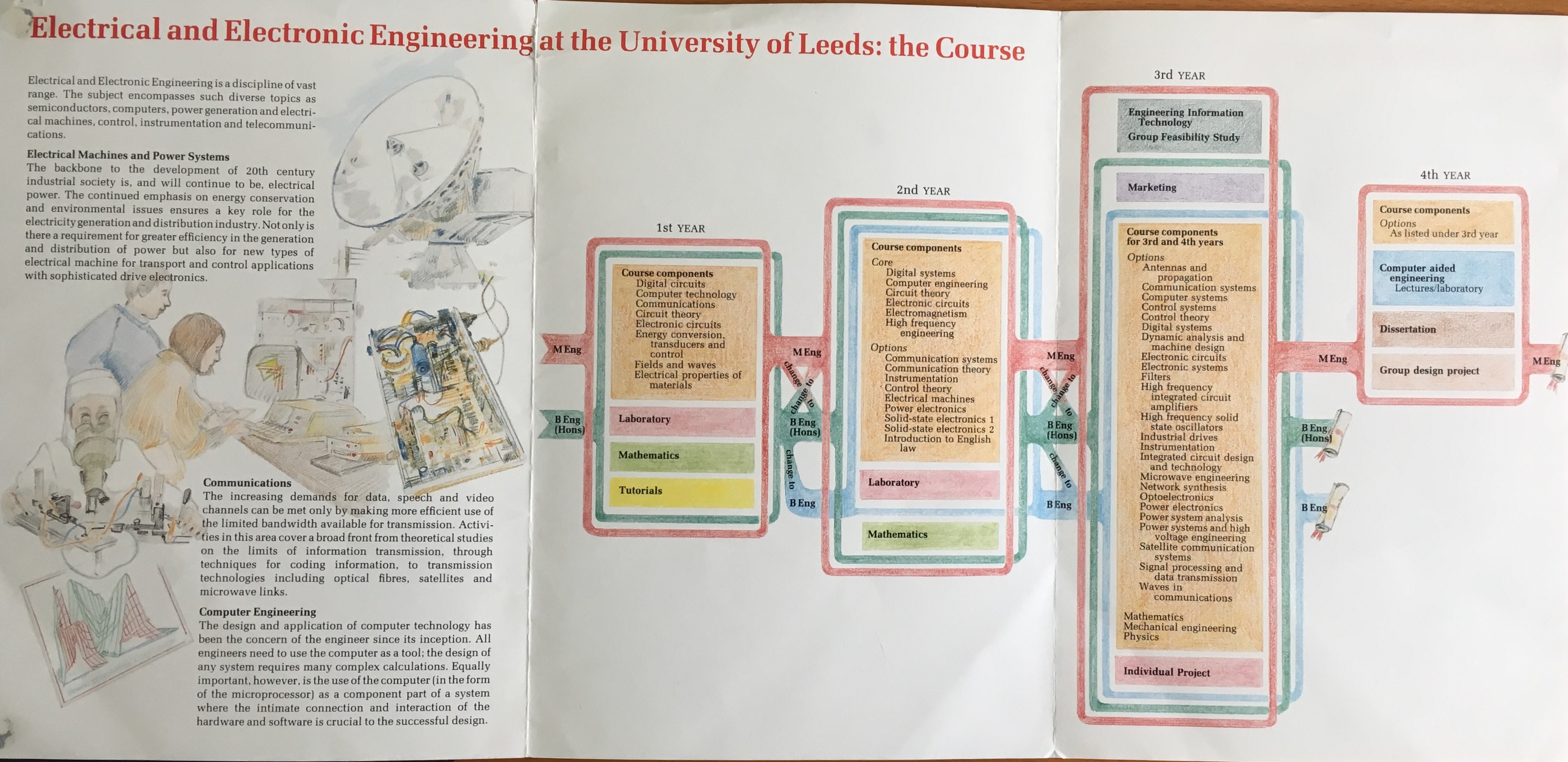

After achieving 11 O-Levels and 4 A-Levels at school in Manchester, I went to study Electronic and Electrical Engineering at the University of Leeds. The three year BEng (Hons) course had options in the final year. I chose Electronic Systems, Communication Systems, Signal Processing & Data Transmission, IC Design & Technology, Satellite Communications, Computers in Design and Manufacture, Microwave Engineering, Solid State HF Amplifiers.

I was very pleased to attain a First Class Honours BEng. On the day of my degree ceremony I was also awarded the Hewlett Packard Prize for High Frequency Engineering by the HP representative who had taught the Marketing course. I admit to being surprised but slightly puzzled by this because I only took two of the three High Frequency courses.

During my degree, I applied for work experience and won a sponsorship from GEC ALSTHOM Traction, for which I worked in the summer holidays and who offered me a position on their graduate trainee scheme on graduation.

GEC ALSTHOM Traction plc and GEC ALSTHOM Transportation Projects Ltd, Trafford Park, Manchester (1991-1992)

Along with about a dozen other graduates, I spent 12 months being rotated around various departments in the two companies on the same site. The training scheme was IEE accredited. I worked on calculating clearances for the vehicles through tunnels for the Manchester Metrolink project and assembled the first prototype board of the microprocessor control system for the traction motors. I wrote new sections of code and debugged others running on an 8086 processor used for controlling the train motors in a Hong Kong subway system. Changes were uploaded to currently in-service vehicles so it was critical to meet deadlines whilst ensuring not to introduce bugs.

GEC ALSTHOM Traction plc, Trafford Park, Manchester & Preston (1992-1995)

As a Graduate Engineer in the Systems Development Department, I designed analogue electronics for signalling compatibility interference current monitors which were newly required pieces of equipment due to the use of squirrel cage inductor motors being introduced with variable frequency 3 phase drives. I was responsible for design, implementation and test of the complete units, to high standards required by safety authorities on the railways. I managed the subcontract design and in-house manufacture and documentation of similar units which required triplication of parts to achieve very high mean time between potentially dangerous failures.

I also spent time working on other major projects such as the Class 91 locomotives for the West Coast Main Line, Docklands Light Rail fully automated system and the TMST trainsets later known as Eurostar.

GEC relocated its design departments to its Preston facility in 1994 which left me with a choice between a long commute and relocation.

Dewhurst plc, Hounslow, London (1995-1998)

Using my knowledge of the rail industry's harsh environmental requirements for electronics, I moved to Dewhurst where this was applied to the indicators and illuminated push buttons used in vandal-resistant applications.

These products were being changed over from small incandescent lamps to LEDs, which the rail industry assumed would be more vulnerable to high energy transients which had been assumed to exist in the standards written for rail vehicles. Therefore the challenge was to meet both the protection and lifetime requirements with a low cost, small factor solution.

On the Lift Indicator side of the business, a new floor indicator display system had been almost completely developed by another engineer who then left. To reduce the number of cables down the lift shaft, and to ease the requirements on the number of cores required in the travelling cable for the lift itself, the LonWorks serial protocol using FTT-10A transceivers had been chosen. However, the first site using this system had been having problems which I quickly traced to interference between the onboard SMPSU and the FTT-10A's comms transformer. Unfortunately this discovery came too late to affect the commercial decision to cancel the project.

LEAX Controls Ltd, Notting Hill & Battersea, London (1998-2004)

Using my knowledge of Echelon's LonWorks protocol, I moved into lighting controls working for a small company who had already achieved successful projects using it. LEAX had one of the first LonBuilders, a multi-node rack based emulator with DOS based IDE using Neuron C. The LonBuilder allows for individual node development and debugging, and network traffic monitoring in the same system. The products often combined a Neuron processor for the networking with a PIC for time-critical deeply embedded processing such as infra-red command reception, third-party serial protocols, keyboard scanning and phase control dimming.

Over the years I developed several lighting control systems for different applications. Office lighting control was designed around energy saving using occupancy sensors to switch off unneeded lights and dimming where daylight is providing sufficient natural light. In these systems, the emphasis is on highly scalable systems with a low cost per channel, controlling fluorescent lighting and being able to interact with local switches, remote controls and system-wide overrides.

In hotels, restaurants and prestige residential properties the emphasis was on phase-control dimming for incandescent and low-voltage halogen lamps controlling typically 10A per channel. Lighting is often used for effect, so scene controls and slow fades become important, as well as interaction with other systems such Audio Visual via interfaces such as RS-232 and special effect lights via DMX-512.

I developed Windows applications in VB5 (& later VB6) to configure, control and monitor these LonWorks systems using Echelon's LNS2 ActiveX control API. LNS has its own object database for each device, variable and connection which it populates by reading data from the network and is only partially editable via the API.

The development team at LEAX was only two or three people. One engineer specialised in PIC firmware, hardware design and PCB layout. Another was taken on for IT support and custom user interface development. I often found myself being the last line of support for the commissioning staff whilst trying to develop new products to compete with the established industry players.

Polaron Controls Ltd, Watford (2005)

I was in the process of joining Polaron Controls when they brought iLight/Zero88, who had been a direct competitor to LEAX. Polaron had their own lighting control range which was mainly sold in the Middle East and used on large projects such as hotels. The department I was asked to manage was also called upon for commissioning duties as well as being employed by other companies in the Polaron Group. I made many improvements to the department including introducing a new system for project planning, timesheet and progress reporting; change control, design review and exemplar reports; composing EMC and LVD policies and test plans.

I provided a mathematical analysis of harmonics produced by dimmers to explain to a major customer that these are inherent in the physics and not a design flaw of the products. I found ways to optimise a heatsink design to reduce the semiconductor temperatures.

A year after the merger, the senior management decided to relocate the lighting control R & D to the iLight/Zero88 office & factory in Wales.

CP Electronics Ltd, Wembley, London (2005-2019)

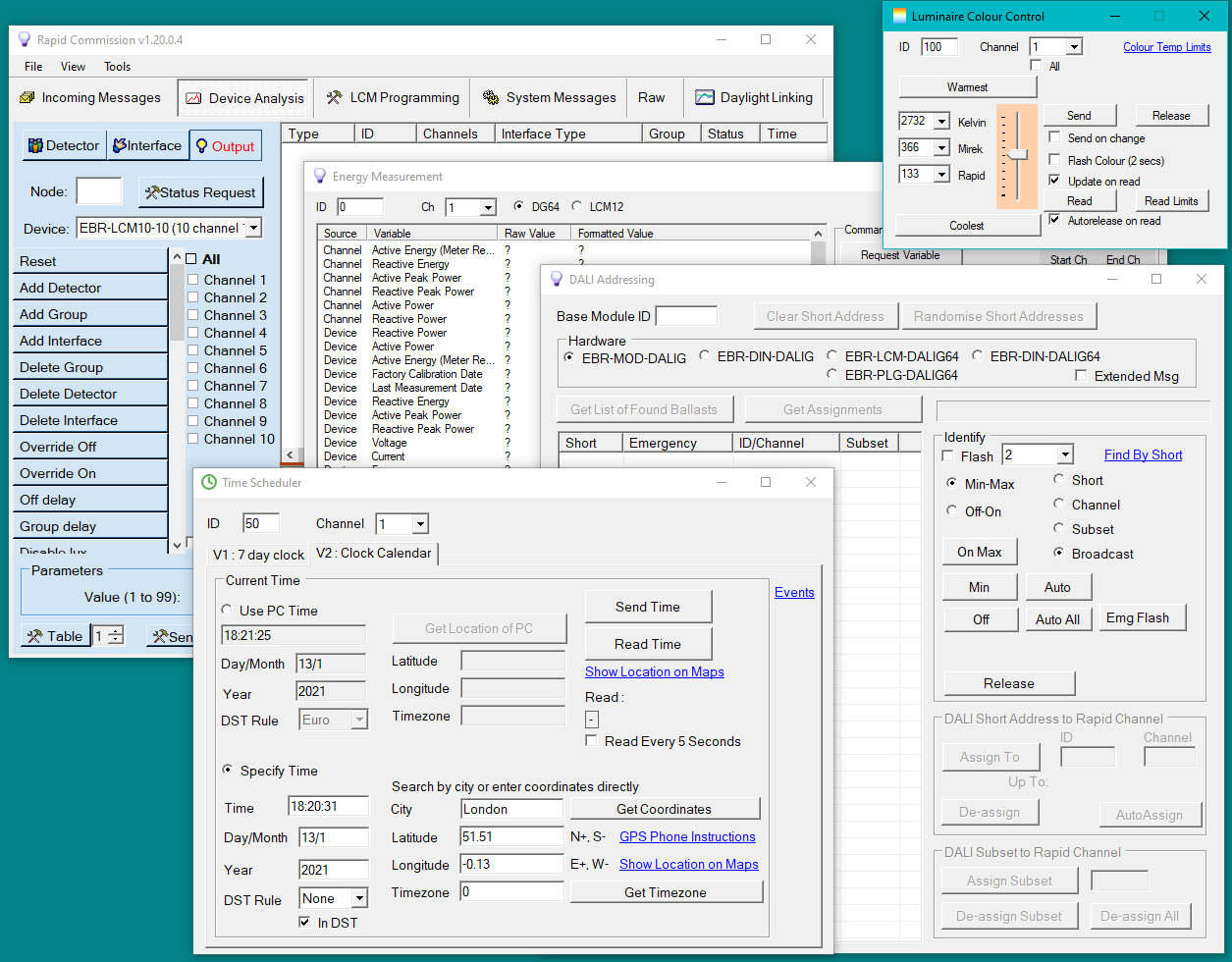

CP Electronics is another lighting control company, with the emphasis on energy saving products. I was initially asked to add features to the existing Rapid range for controlling fluorescent lights in office applications. Offices have increasingly adopted dimmable fluorescent lighting to reduce glare and save energy, and control of these was moving from an analogue 1-10V signal to a digital DSI or DALI signal.

Digital dimming is more accurate and consistent across fittings and allows for more features. DSI was a proprietary although widely accepted protocol from Tridonic but was superseded by the industry standard DALI which allows for addressing, readback and fading with some intelligence at the driver.

After adding the feature to the Rapid Lighting Control Module for DALI readback to detect lamp failure, I went on to add emergency test and reporting features. A major project was the improvement in the daylight linking feature so that instead of channels acting independently, they could be set up to give a graduated effect across the room to compensate for the light from windows.

A feature that makes LCMs easy to deploy is that each channel acts as if it were one electrical circuit - all luminaired plugged into it are at the same on or off state and dimmed at the same level. However, the downside of this is that star cabling arrangement can get unwieldy and doesn't suit some layouts such as long corridors, chilled beams or exposed ceilings. In those cases, the installer wants a single signal cable that goes to all the luminaires and controls them via a software address. DALI supports this via short and group addressing, and I developed a set of gateway products which use the LCM logic on the CAN bus side and drive up to 64 DALI short addresses. This was later extended to allow occupancy sensors and control switches on the same cable.

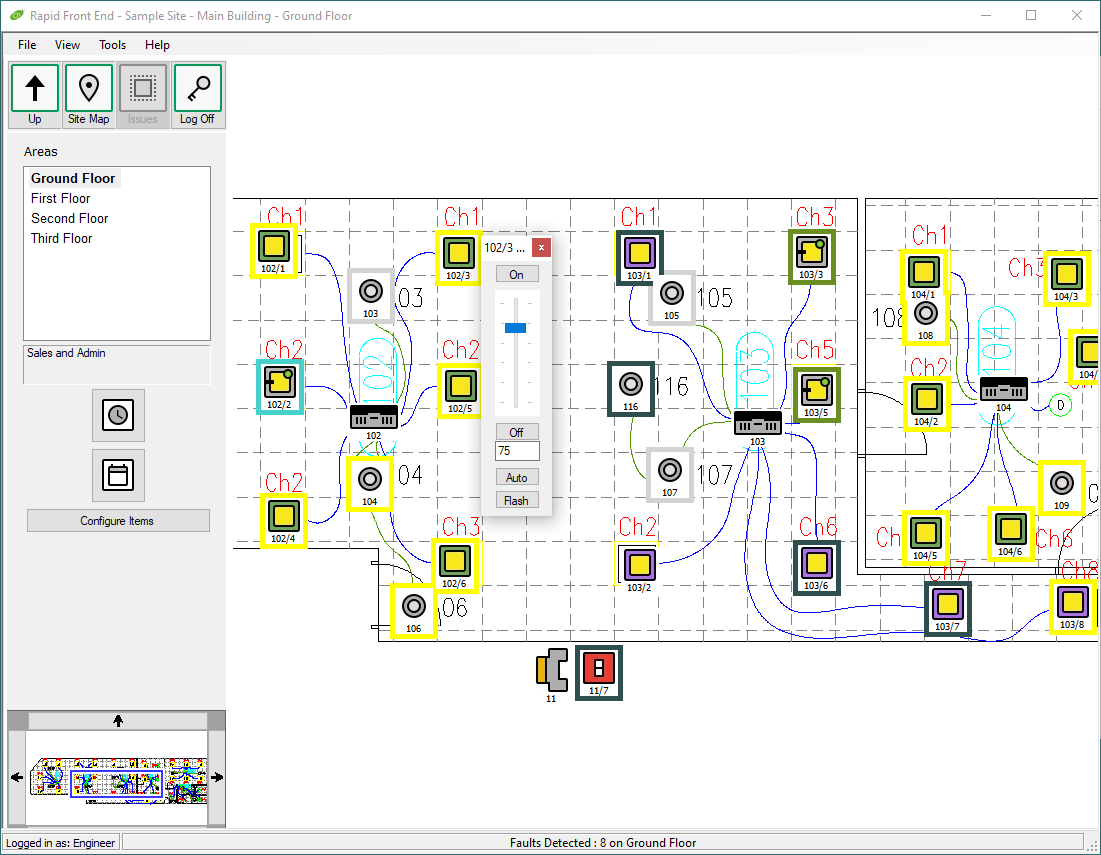

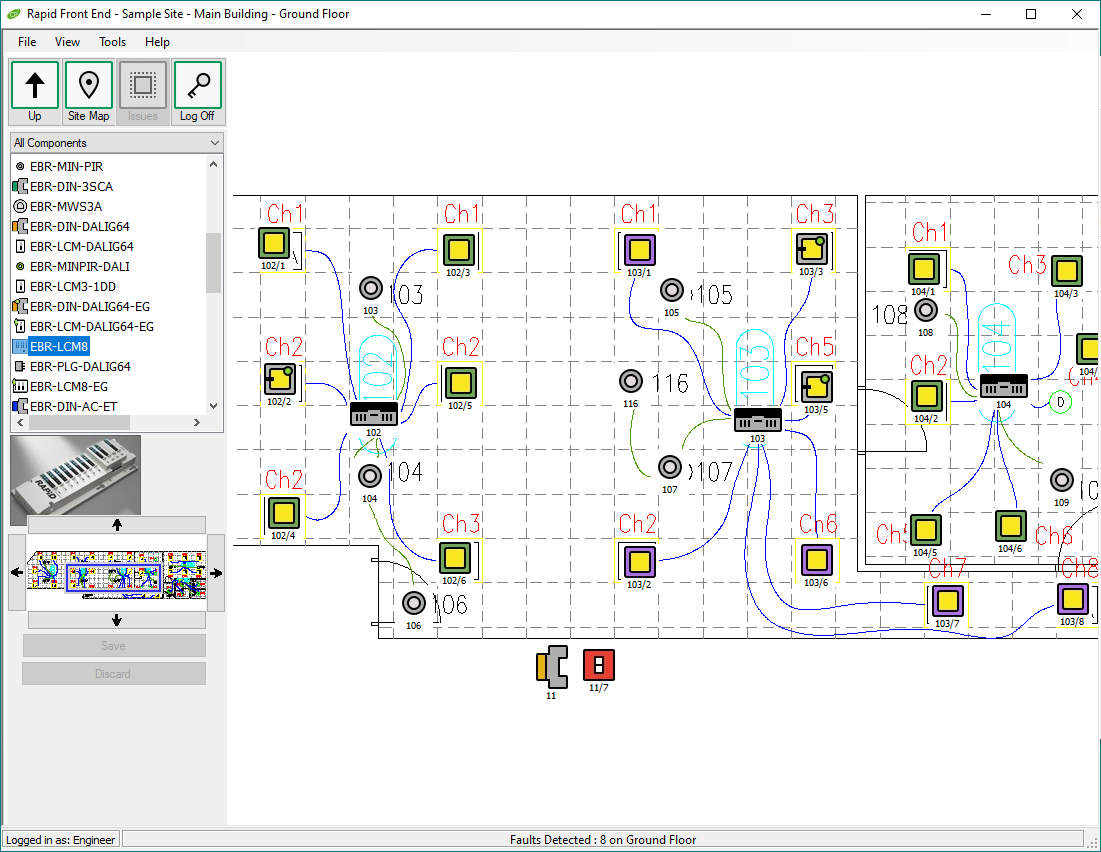

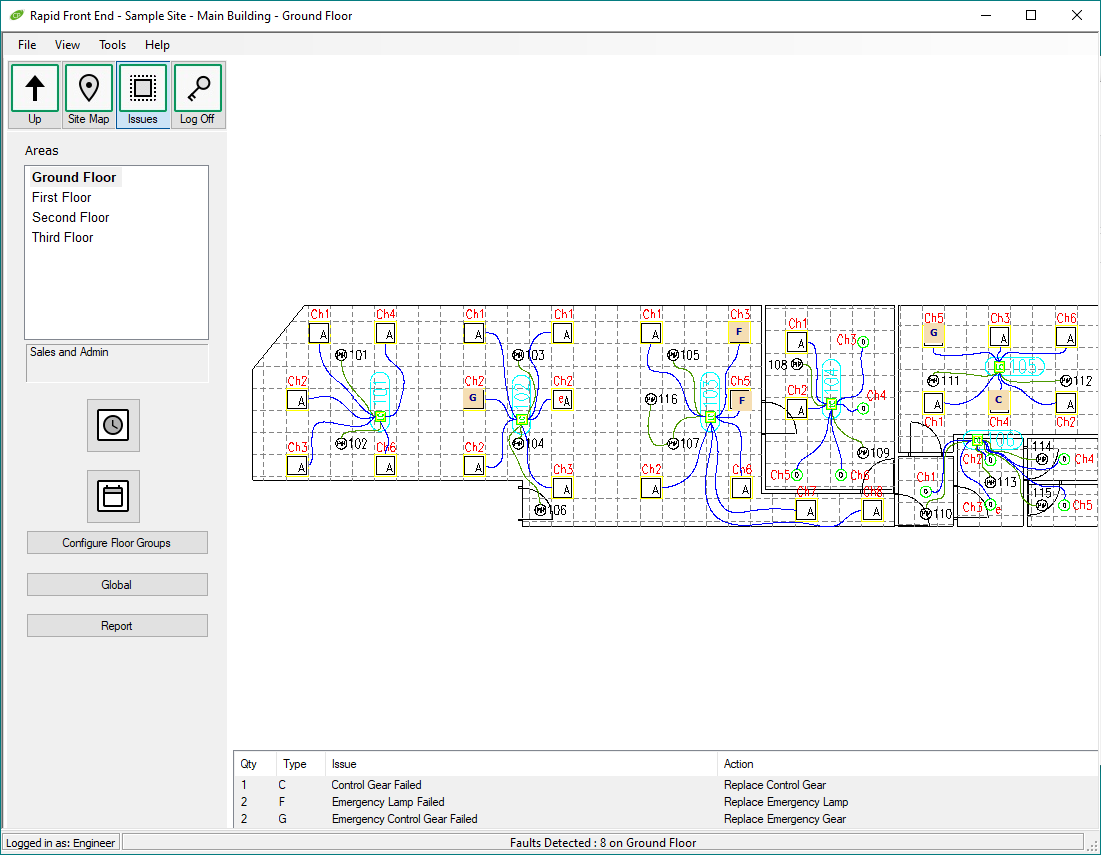

Having picked up development of our CAN based commissioning software package, I was in a position to single-handedly develop from scratch our plan-based monitoring and reporting package in VB.NET and SQL Server. There were many new technologies to learn and a high risk that the project might not complete - a fate I had seen occur to the same project at two previous companies. So we agreed to eliminate a couple of aspects of the design that weren't strictly necessary and to attempt the higher risk items first - if they failed, at least that would be known before spending too much time. However, the project was a success and allowed CP to sell many more lighting control systems than if that product has not been an option.

Later I wrote a TCP socket based communications layer which acts in parallel with the CAN layer so that our Ethernet Area Controllers could be handled as if they were on the CAN backbone. Discovery, connection and disconnection was handled seamlessly on a background thread. I also wrote some Windows tools for diagnosing TCP problems between the PC and the Area Controllers which could occur since that option is reliant on the building's IP infrastructure.

I led the development of a mesh radio protocol used with the An-10 range of products based on the sub-GHz ISM band CC1101. At this time, commercial radio modules were too expensive or inflexible for our requirements and we wanted to be able to make a single board product. Designing such a protocol requires inventing many mechanisms to ensure reliable and secure delivery of messages in a timely manner. The protocol had to incorporate support for all the application level features that were demanded of a next-level lighting control system.

Another product range for which I wrote the firmware was the D-Mate system which was DALI based using the existing 16-bit frames but to implement multi-master bit-timing requirement as was much later adopted by the IEC Committee. Avoiding, detecting and recovering from collisions was a particularly difficult challenge given the bit times and processor capabilities. Another product in this range handled on-the-fly message conversion without using a store-and-forward approach, whilst running in a tiny PIC12.

A couple of multi-year projects were the design and implementation of energy measurement subsystem and a "circadian rhythm" system for Rapid. The former used a single measurement circuit with an algorithm that could measure energy consumption per channel, backed up with a full cloud based reporting system. The latter requires slow colour and brightness changes over time with a fully featured programmable clock-calendar device and handling of user override inputs as well as the interactions of occupancy sensors and scene plates.

With my history of developing DALI products, I was nominated to represent the company at the IEC 62386 standardisation meetings. After having only seen the output of this process for many years, it was fascinating to see what goes on and how competitors work together to agree a standard. The same set of people were also involved in the trade association which owns the DALI trademarks and certification process, but that is outside and separate from the IEC. DiiA (now DALI Alliance) Technical and Certification Working Group meetings quickly became a large consumer of my time. I was then in the unusual position of having three roles regarding DALI - being on the IEC Committee and DiiA TCWG as "law maker", as the CP internal expert as "compliance manager" and as a product designer subject to these rules.

Since I had been in charge of our Infra-red protocol for many years, I was passed the completion and maintenance of the IR based programming handset. This was a large project because of the menu system required to cope with our large range of products and variants. Hundreds of commands are organised in a multi-sheet Excel spreadsheet, parsed by a VB.NET program into a file which is then uploaded into the handset by means of a USB bootloader from a flash drive. The handset can also program some unpowered devices over a serial link using a USB cable with handset powered isolator dongle, and has An-10 radio capability.

Hanwha Phasor, Farringdon, London (2021-)

Phasor Solutions have been developing phased array antennas for high performance satellite broadband internet connectivity. They were acquired by the Hanwha Systems group of Korea which enabled the company to expand and commercialize their product range. I joined a team of four software engineers who worked closely with a substantial hardware team to integrate the custom ASICs into the complete product.

Since the project had been in development for a few years, each board used different microcontrollers and IDEs, and new versions were in development. In my first year, most of the work was with STM32F4 using Keil uVision 5 and STM32H7 with Keil and STM32CubeIDE, as well as IAR Embedded Workbench for an STR9 board. My contributions were a custom QSPI driver for the ISSI 25LP512M NOR flash, improvements to the file system including updating LittleFS and working with SPI-like devices such as the HMC305 RF attenuator.

In my second year, my time was split between embedded C projects and a C# Windows WinForms application to act as a substitute for the modem. I went from zero previous knowledge of the language in 4.5 months to a fully featured 4500 line .NET Core 6 multithreaded program incorporating TCP sockets, NTP client, spectrum analyzer integration using named pipes, 3rd party libraries for SGP4 orbital calculations and LiveCharts2 for graphing as well as a web view and web APIs. The project was developed while the company was trying out Scrum methodology with 2 weekly sprints where I was the sole developer on that codebase in a mixed discipline team, giving me an insight into the strengths and weaknesses of modern Agile practices.

Back on the embedded side, I developed an SPI driver for the Ethernet switch KSZ8775, and started the basis for a new product using FreeRTOS and LwIP for a 100BASE-T1, 100 Mbit connection over single pair using the dual core STM32H745 using STM32CubeIDE.